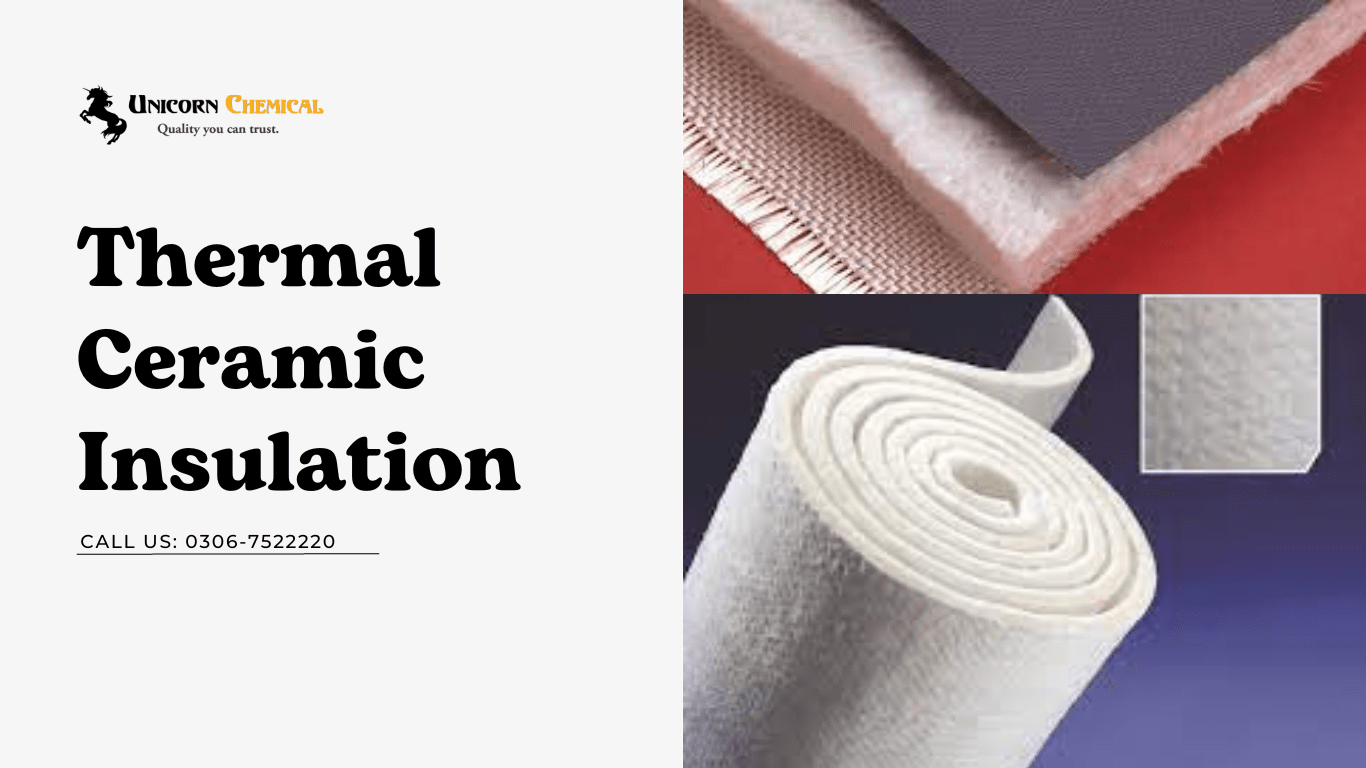

Thermal Ceramic Insulation

Thermal ceramic insulation is a type of insulation material that is made from ceramic fibers and is use to provide thermal insulation in high-temperature environments. It is commonly use in industries such as metallurgy, petrochemical, and power generation, as well as in residential and commercial buildings for heat retention.

How Thermal Ceramic Insulation is made?

Thermal ceramic insulation is typically made by combining ceramic fibers and binders to create a mat-like material. The fibers use in the insulation are made from high-temperature ceramics that are able to withstand extreme heat and prevent the spread of fire. The binders help to hold the fibers in place and improve the material’s structural integrity.

The mixture is then mold or felt into desire shapes, dry, and fire in a kiln to remove any residual moisture and enhance its insulating properties. Some products may also be treat with coatings or additional materials to improve their performance in specific applications.

Benefits of Thermal Ceramic Insulation

Following are the benefits of Themal Ceramic Insulation:

High Temperature Resistance

One of the main benefits of thermal ceramic insulation is its high temperature resistance. It can withstand temperatures up to 2300°F, making it ideal for use in applications that require insulation in high-heat environments.

Low Thermal Conductivity

Additionally, thermal ceramic insulation has low thermal conductivity, meaning it is able to slow the transfer of heat and keep temperatures consistent.

Low Density

Another advantage of thermal ceramic insulation is its low density. Compared to other insulation materials, thermal ceramic insulation is much lighter and easier to handle. Making it easier to install in hard-to-reach areas. It also has a low shrinkage rate and high dimensional stability. Meaning it maintains its shape and size even in extreme temperature changes.

Fire Resistant

Thermal ceramic insulation is also fire-resistant and does not release toxic fumes when exposed to high temperatures. This makes it an ideal choice for use in applications where fire safety is a concern, such as in industrial boilers or in buildings near high-risk areas.

For which type of buildings thermal ceramic insulation is best?

Thermal ceramic insulation is best suited for buildings or facilities that require insulation in high-temperature environments. This type of insulation is particularly effective in industries such as metallurgy, petrochemical, and power generation, where temperatures can reach several hundred degrees Celsius.

Additionally, thermal ceramic insulation is also suitable for use in residential and commercial buildings that require heat retention. This can include buildings that are located in cold climates or those that require additional insulation for energy efficiency.

In summary, thermal insulation is best for buildings or facilities that require insulation in high-temperature environments, as well as for residential and commercial buildings that need additional insulation for heat retention and energy efficiency.

Applications of Thermal Ceramic insulation

Thermal insulation is a type of material use to improve the thermal performance of various structures and equipment. This material is widely used in a range of industries and applications due to its excellent insulation properties and high temperature resistance. Here are some of the common applications of thermal ceramic insulation:

Furnaces and kilns

Thermal insulation is use in high-temperature furnaces and kilns to reduce heat loss and improve energy efficiency. It is also use to protect personnel and equipment from high temperatures.

Industrial pipes and valves

Thermal ceramic insulation is use to insulate pipelines, valves, and other equipment in the petrochemical, oil, and gas industries. This helps to maintain the temperature of the fluid being transported and prevent heat loss.

Automotive industry

Thermal insulation is use in automotive applications, such as exhaust systems and catalytic converters, to withstand high temperatures.

Aerospace industry

Thermal insulation is use in aerospace applications, such as in the insulation of spacecraft and satellites, to protect against heat loss and provide thermal protection.

Power generation

Thermal insulation is use in power generation facilities, such as power plants and boilers, to reduce heat loss and improve energy efficiency.

Building insulation

Thermal insulation is also use in building construction, such as in walls, roofs, and floors, to improve energy efficiency and reduce heat transfer.

Thermal ceramic insulation is best for roof walls or basement or which place?

The suitability of thermal insulation for roof, walls, or basement depends on the specific requirements of the building and the local building codes.

Roof

Thermal insulation is a good option for roof insulation as it can withstand high temperatures and provide effective insulation against heat loss.

Walls

Thermal insulation is also a good option for wall insulation as it can provide effective insulation against heat transfer, helping to maintain indoor temperature and reduce energy consumption.

Basement

Thermal ceramic insulation can also be use in basement insulation to provide effective insulation against cold and dampness, helping to maintain indoor temperature and reduce energy consumption.

In general, it’s important to consider the specific requirements of the building, the local building codes, and the insulation requirements when choosing the type of insulation to use in a specific area. It’s always advisable to consult a professional to ensure the most suitable insulation solution is select for the specific needs of the building.

How to do thermal ceramic insulation?

Thermal ceramic insulation involves the use of ceramic materials to insulate a surface or structure and reduce heat transfer. The steps to install thermal ceramic insulation include:

Preparing the surface

Clean and dry the surface to be insulate, ensuring it is free of dirt, dust, and other contaminants.

Measuring the surface

Measure the surface area to be insulate, including any gaps and spaces.

Cutting the insulation

Cut the ceramic insulation to fit the surface, allowing for a snug fit with minimal air gaps.

Installing the insulation

Install the ceramic insulation by placing it in the desired position and securing it in place with adhesive or mechanical fasteners.

Sealing the edges

Seal any gaps or edges around the insulation to prevent air infiltration.

Checking for air leaks

Check for air leaks and make any necessary repairs to ensure a tight, well-insulated surface.

Note: It is important to follow the manufacturer’s instructions carefully when installing thermal insulation to ensure optimal performance and long-lasting results.

Conclusion

In conclusion, thermal ceramic insulation is a highly effective insulation material that offers numerous benefits for high-temperature environments. Its ability to withstand high temperatures, low thermal conductivity, low density, and fire resistance. Make it a popular choice for a wide range of applications.

Thermal ceramic insulation is a versatile material with a wide range of applications in various industries. Its excellent insulation properties and high temperature resistance make it an ideal choice for applications where thermal performance is critical.